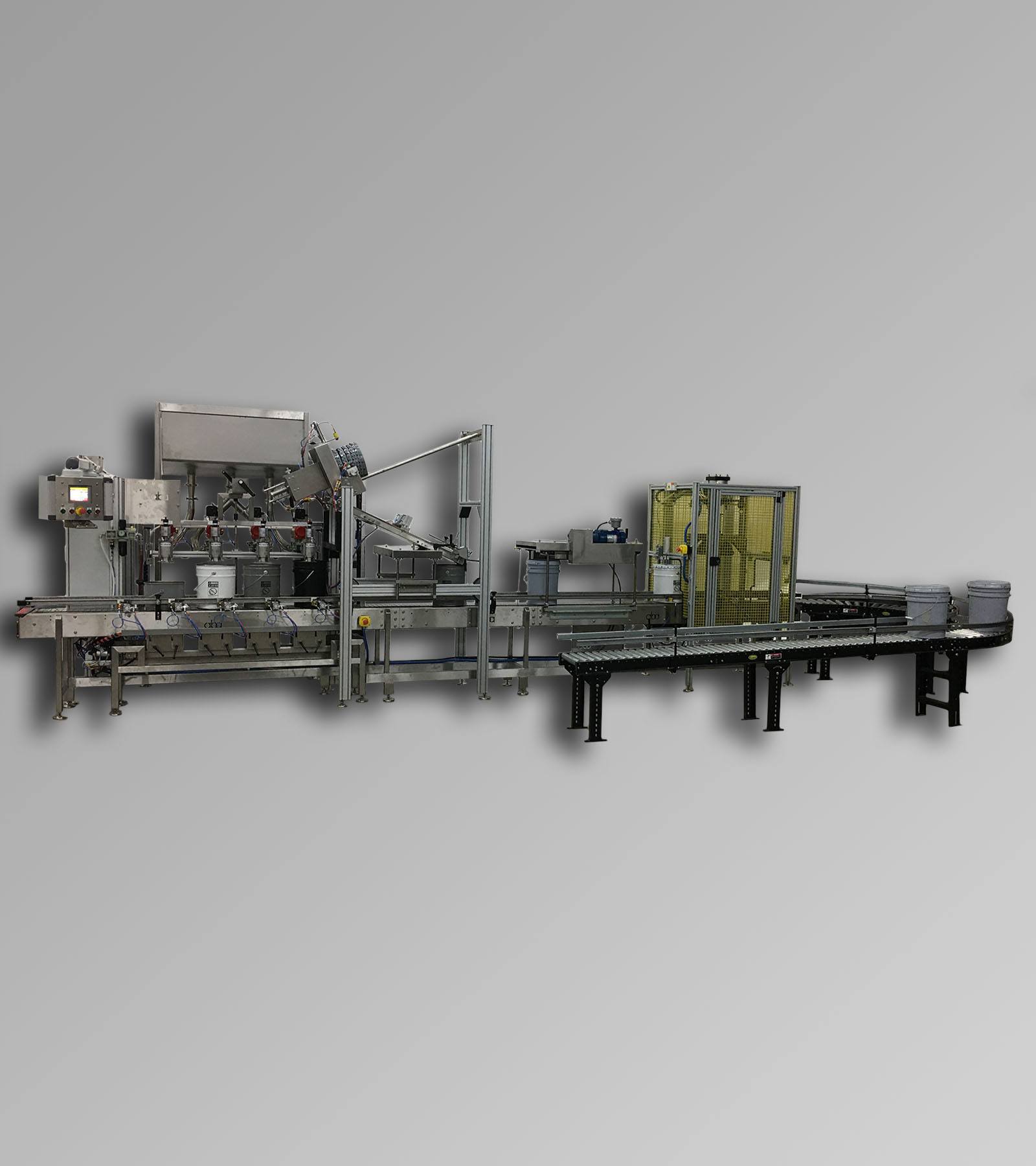

ABA-M396 is a 4 head, fully automatic, net weight filling machine designed for a C1D1 area and featuring a variety of additional equipment all of which serves to make it a powerhouse machine.

Although ABA-M396 is a 4 head machine, it was designed by our customer to fill on only 2 heads at a time in order to prevent cross contamination of different products. As with all of our custom machinery, this system best meets the needs of our customer and increases their productivity and throughput. The stainless steel frame, C1D1 rating, and additional equipment and features all serve to make this fully automatic filling machine a boon to whatever filling line it is a part of.

This Class 1 Division 1 (C1D1) machine includes an intrinsically safe mouse on the pendant arm which controls the HMI. The mouse makes navigating between screens and inputting information faster and easier than attempting to use a C1D1 screen cover. This is just one of the many ways ABA innovates and adjusts to produce faster, more efficient and more accurate machines which subsequently are more profitable, productive, and valuable.

The HMI itself stores 100 recipes, making it easier to change between sizes and products being filled while maintaining accurate and repeatable results.

Due to the different products and containers being filled and used on this machine, this machine showcases a number of lidding options:

- Our 5 gallon lid placer for both plastic and metal lids features a hopper for additional capacity, a low lid stack notification system, and adjustable release paddles to accommodate different sized and shaped containers. The in feed line stops on this unit also automatically space incoming containers. This unit allows for an operator to pre-load a large number of lids which are then plucked and placed from the hopper onto the chute and placed onto the containers as they pass beneath it. This unit can additionally be supplied with a bung orientation system for locating and directing the bung to the correct position.

- Our powered roller lid press for the plastic lids utilizes a 0.5 HP motor along with the motive force of the conveyor to firmly press lids into place. This particular press was designed for a C1D1 area and features an intrinsically safe motor to power the unit. As with all of our lid presses, this is supplied with a hand crank on one corner of the press for simple height adjustment. A stainless steel sheet metal guard covers these chains and sprockets for operator safety. Our powered presses feature 5 lead in rollers and 6 large powered rollers.

- Our lid crimper station for the metal lids features a customized crimp tool to best fit the containers used by our customers. Enclosed by safety guarding and equipped with an emergency stop button, this unit is both safe and efficient.

- A no lid detector is located on the front of the lid crimp unit to catch any potential lidding misses. This stops the conveyor and cycle until the situation is remedied and then the cycle can be resumed. This helps to prevent spills and dangerous contamination.

Our ever popular cone style fill heads contribute to the usability, cleanliness, and productivity of this filling machine. Although the ABA-COV-85F heads were supplied with this machine, the versatility of our cone style fill heads as well as the quick and easy changeovers makes it easy to switch out fill heads for maximum results and throughput. The ABA-COV-85F fill heads have a 2 inch S-line inlet, a 3.32 inch outlet, and a 4 inch S-line flush connector.

Quality, safety, and functional custom design are all imperative to us at ABA and we strive to make each of our machines the best fit for our individual customers. Please contact us today to find out more about this or any of the other machines and equipment we have supplied or to work directly with us to design a machine to best suit your needs. Call (803) 396-0621, email sales@abaltd.com, or request a quote from our website.