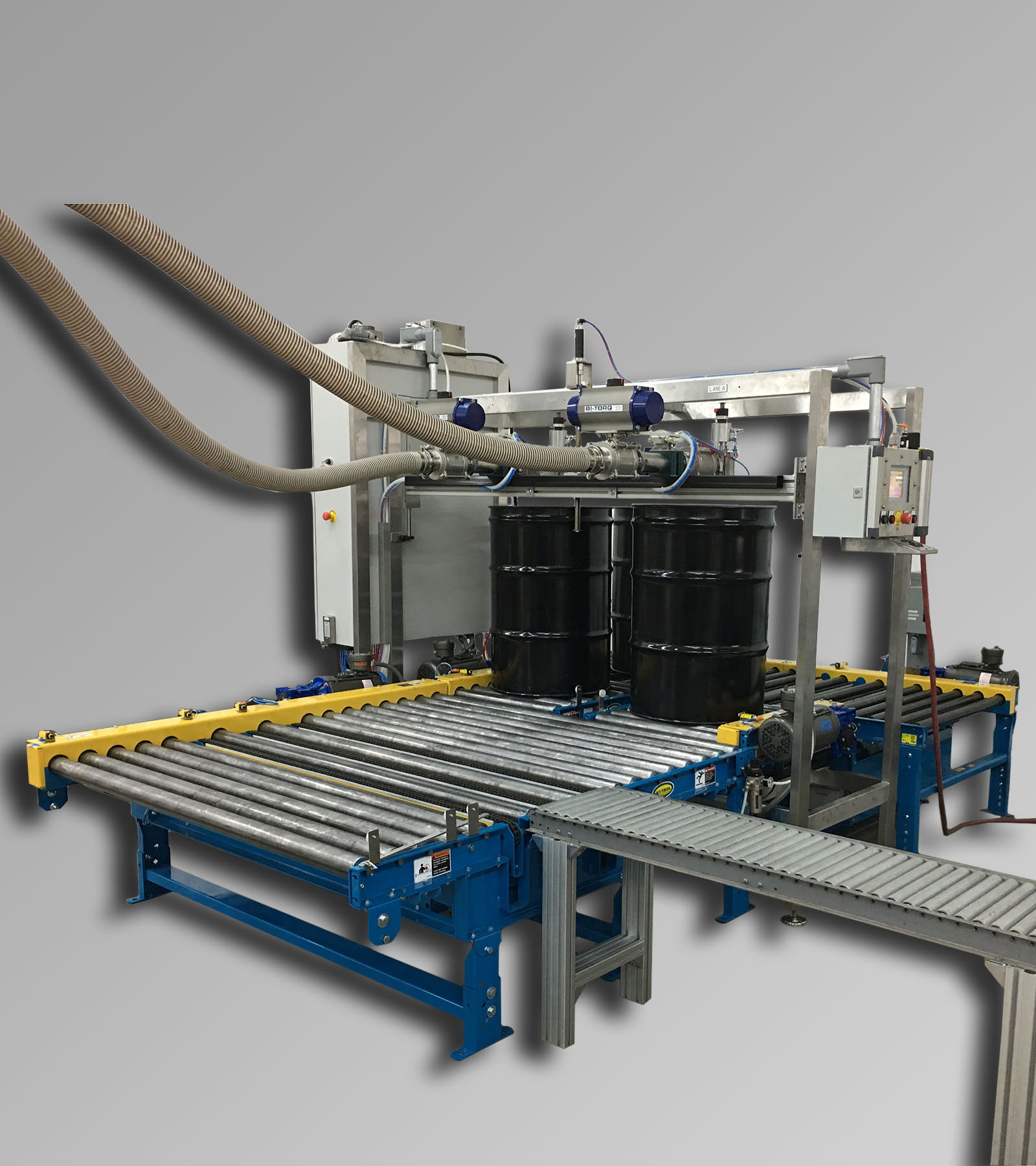

Our newest drum filling machine, ABA-M387, is a net weight, top fill, 2 head, fully automatic filling machine. This unique machine features a number of innovative designs to help simplify the fill process and remove some of the burden from the operator.

The pop up conveyors on this machine assist with transporting the drums to the fill stations. As the drums are conveyed on initially, pop up conveyor sections direct the drums into the two fill stations and allow two more drums to be waiting behind them. This increases the speed and efficiency of the machine and works in conjunction with the alternating fill stations to ensure that the machine is constantly filling drums.

The alternating fill stations were designed as such in order to keep a continuous flow of high viscosity extruded product to the drums. The alternations work as such: the machine fills lane 1 and lane 2 is conveyed into place. As lane 1 finishes and the drum is conveyed out of the fill area, lane 2 begins to fill. While lane 2 is filling, the next drum is conveyed into lane 1 so it is ready to start filling as soon as lane 2 finishes, and so on. This is an extremely efficient system and creates maximum throughput on this machine.

ABA-M387 also features our new ABA-COV-85BO fill heads which have built in air shear (blow off) or nitrogen purge technology. These cone style fill heads were specifically designed with high viscosity products in mind. When the fill is completed, the forced air helps to blow off or to shear the product from the cone. This is a very effective way to prevent product getting hung up or dropping after the container has moved away.

To get more information about this or any of the other drum filling machines, liquid filling machines, or equipment we have, please call or email today.