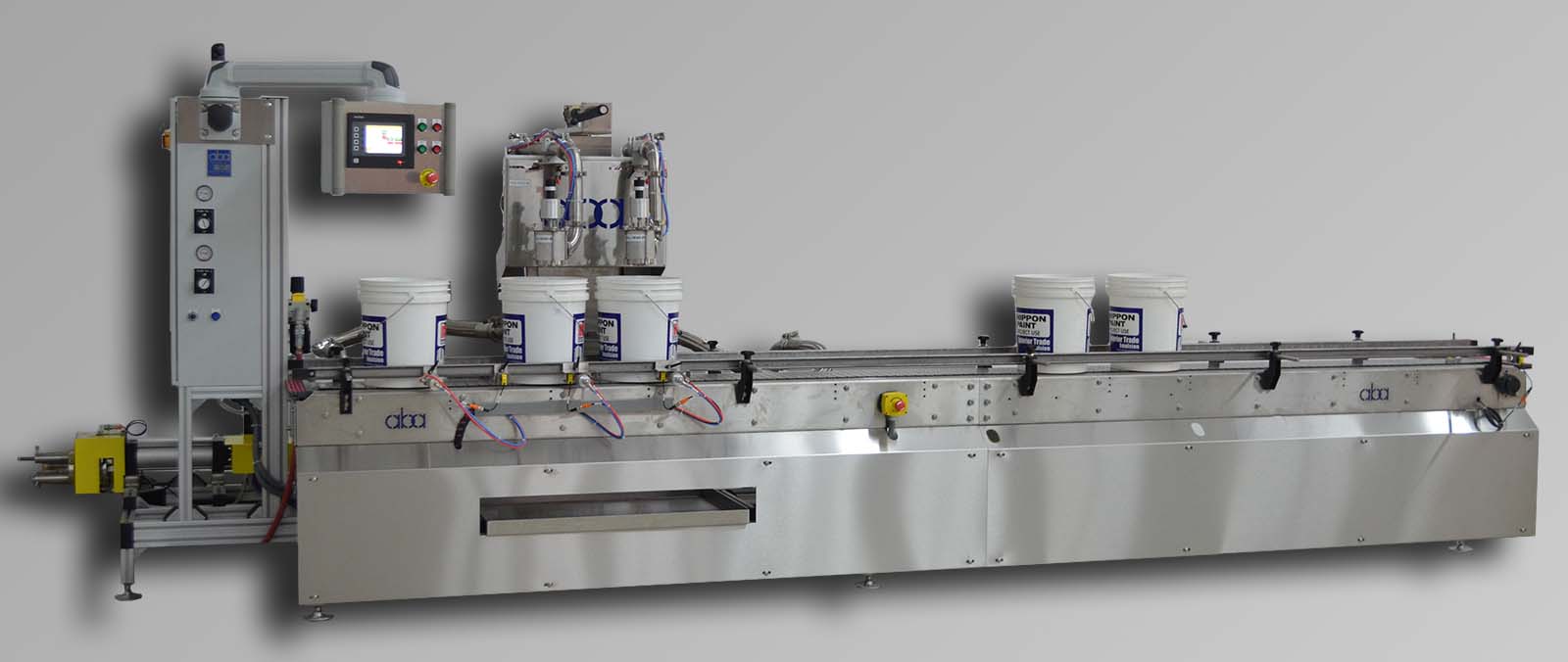

ABA-M420 is a dual head volumetric filling machine with our popular swing frame design. The benefit of the swing frame design is the simplicity of cleaning, flushing, and priming of the pumps and fill heads. This is achieved by pushing the fill heads around on their swivel joints so that they hang over the rear of the machine. The operator would then position a flush tank beneath the heads and initiate the flush cycle on the HMI. The machine will then continously flush until the operator stops the flush function. This is not only a simple procedure, it saves time and eliminates the need to perform extensive clean up as well.

This machine features our 1 gallon double acting volumetric piston pumps, the ABA-80's. As with all of the pumps we produce, these are double acting. We believe this is a superior way to pump, because it increases the efficiency, lifespan, and accuracy of the pumps. Double acting means that product is on both sides of the piston at all times. This means that there is no unnecessary wear and tear on the components of the pump which results in a longer lifespan for those parts as well as the pump as a whole. This also creates a more efficient fill cycle because, for instance, when filling a 1 gallon can, 1/2 gallon would be filled on the forward stroke and 1/2 on the backward stroke. This eliminates excess "travel time" as the pump is immediately ready to fill the next container instead of having to return back to the home position.

This machine is being supplied with our ABA-COV-85QTS fill heads. These heads have a 2 inch S-line inlet and a 1.85 inch diameter outlet and are primarily used for filling quart and gallon cans. Our cone style fill heads eliminate the stringing problems associated with capillary tube style heads and have a clean cut off when they snap closed. Our fill heads are easy to clean and maintain and can also easily be switched out for a different size fill head when performing a size changeover.