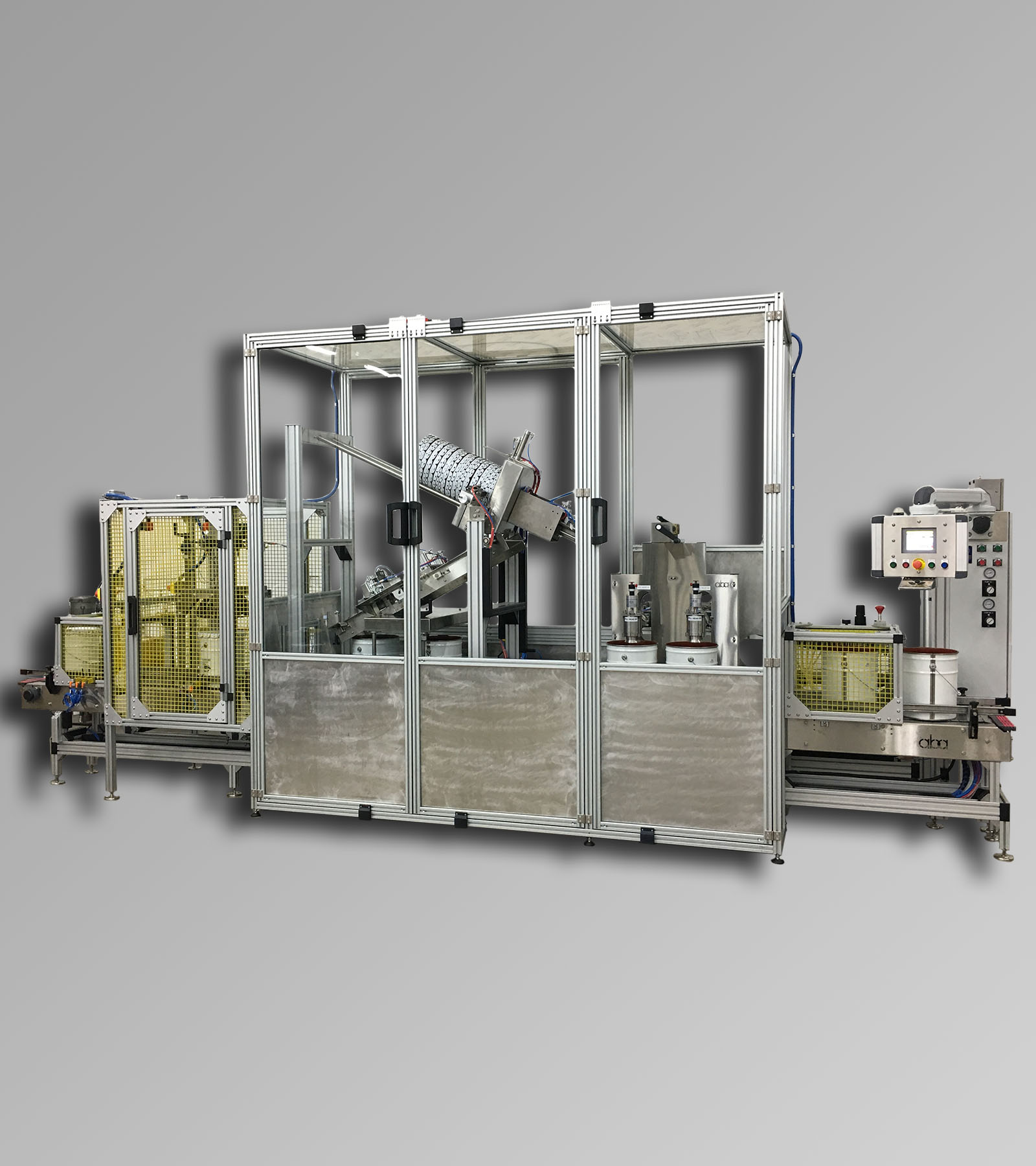

ABA-M439 is a two head volumetric filling machine designed to meet C1D1 standards for a hazardous environment. This pail filling machine features a lid placer with bung orientation, a lid crimper, fume extraction enclosure, and 5 gallon double acting piston pumps.

This paint filling machine will be placed in a hazardous filling environment and is therefore made to meet C1D1 (Class 1 Division 1) standards. ABA offers a wide range of intrinsically safe filling machines, from fully to semi-automatic and both volumetric and net weight. Like many of our C1D1 machines, ABA-M439 features an intrinsically safe mouse to use in place of the touch screen HMI in order to prevent any static buildup. This is a simple way to navigate the screens safely and efficiently.

The 5 gallon lid placer unit is designed for placing either plastic or metal 5 gallon lids. The chute on this machine is also outfitted with a lid bung orientation system to bring the bung to an exact location as specified by the customer. Adjustable release paddles at the end of the chute allow for the placement of round, square, and rectangular lids, making this a very versitile piece of equipment. Automatic lid priming keeps the chute full and ready for the next container, and the hopper is equipped with low and no lid sensors. The machine will notify the operator when there is a low lid stack and will automatically stop when it runs out of lids.

This machine is also being supplied with a fume extraction enclosure which surrounds the filling and lid placing area. This enclosure protects workers from breathing in fumes and vapors.

The 5 gallon metal lid crimper is a single stage electronic crimper which is fully surrounded by protective mesh and can be accessed via a door at the front of the machine.

Anthony Barber Associates' 5 gallon pumps, the ABA-2000, provide the filling power on this machine. These hard-working and highly efficient pumps are double acting, fully adjustable, and easy to clean and maintain. They feature cast end caps, elbows and tees and stainless steel and Teflon wetted parts. A stroke adjustment handle allows the operator to make quick and easy volume changes.

For additional information or if you have any questions, please contact us at email sales@abaltd.com or by calling (803) 396-0621.