LPHSC-V |

RT-60-IN |

RT-60-OUT |

FILL-BFGEA-X |

|

| Description |

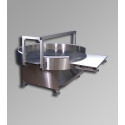

The ABA-LPHSC-V is a 5 gallon plastic or metal lid placer. This unit has an ergonomically low loading conveyor which is especially beneficial for higher speed applications and loading heavy metal lids. Stacks of lids are conveyed into the lid stacker, raised, and rotated to the escapement chute. This unit self-centers the lids on the containers as they pass below it. Features:

|

The ABA-RT-60-IN is a 60 inch diameter in feed rotary table. When used as part of an automated line, it allows operators to pre-load large quantities of containers at the start of the line to enhance and speed up the filling process. Features:

|

The ABA-RT-60-OUT is a 60 inch diameter out feed rotary table. When used as part of an automated line, it collates containers as they come off the conveyor and allows for a large quantity of containers to sit until they are ready to be moved forward to the next stage of the process. Features:

|

Bottom Fill Gravimetric Electronic Automatic eXplosion-Proof Liquid Filling Machines The ABA-FILL-BF Bottom Fill Series are designed to fill below the level of the liquid to minimize foaming and protect against exposure to static prone products. Submerging the fill nozzle beneath the product as it is filling prevents air in the product, and helps to eliminate foaming and static buildup. This in turn allows the products to be filled more quickly and in a safer manner. On our bottom fill machines, the diving lance style fill head is lowered into the bottom of the container utilizing either a Servo motor or a pneumatic air cylinder. Both methods offer accurate and easily adjustable filling and tracking. Once the fill cycle starts, the fill carraige slowly rises, drawing the fill head(s) up as it goes. As the container is filled with liquid, the head of the fill lance remains submerged under the level of the liquid. These paint filling machines are highly accurate and will increase the efficiency of any plant. Features:

|

| Short Description |

The ABA-LPHSC-V is a 5 gallon plastic or metal lid placer with a stack, lift, and load assembly and an escapement chute. |

The ABA-RT-60-IN is a 60 inch diameter in feed rotary table. |

The ABA-RT-60-OUT is a 60 inch diameter out feed rotary table. |

Bottom Fill Gravimetric Electronic Automatic eXplosion-Proof Liquid Filling Machines The ABA-FILL-BFGEA-X is an electronically controlled, automatic, explosion proof net weight filling machine which is designed to bottom fill containers from half pint to 5 gallon pails. |

| SKU |

LPHSC-V

|

RT-60-IN

|

RT-60-OUT

|

FILL-BFGEA-X

|

| Manufacturer |

No

|

No

|

No

|

No

|

| Notes |

No

|

N/A

|

N/A

|

No

|

Please wait...

Please wait...