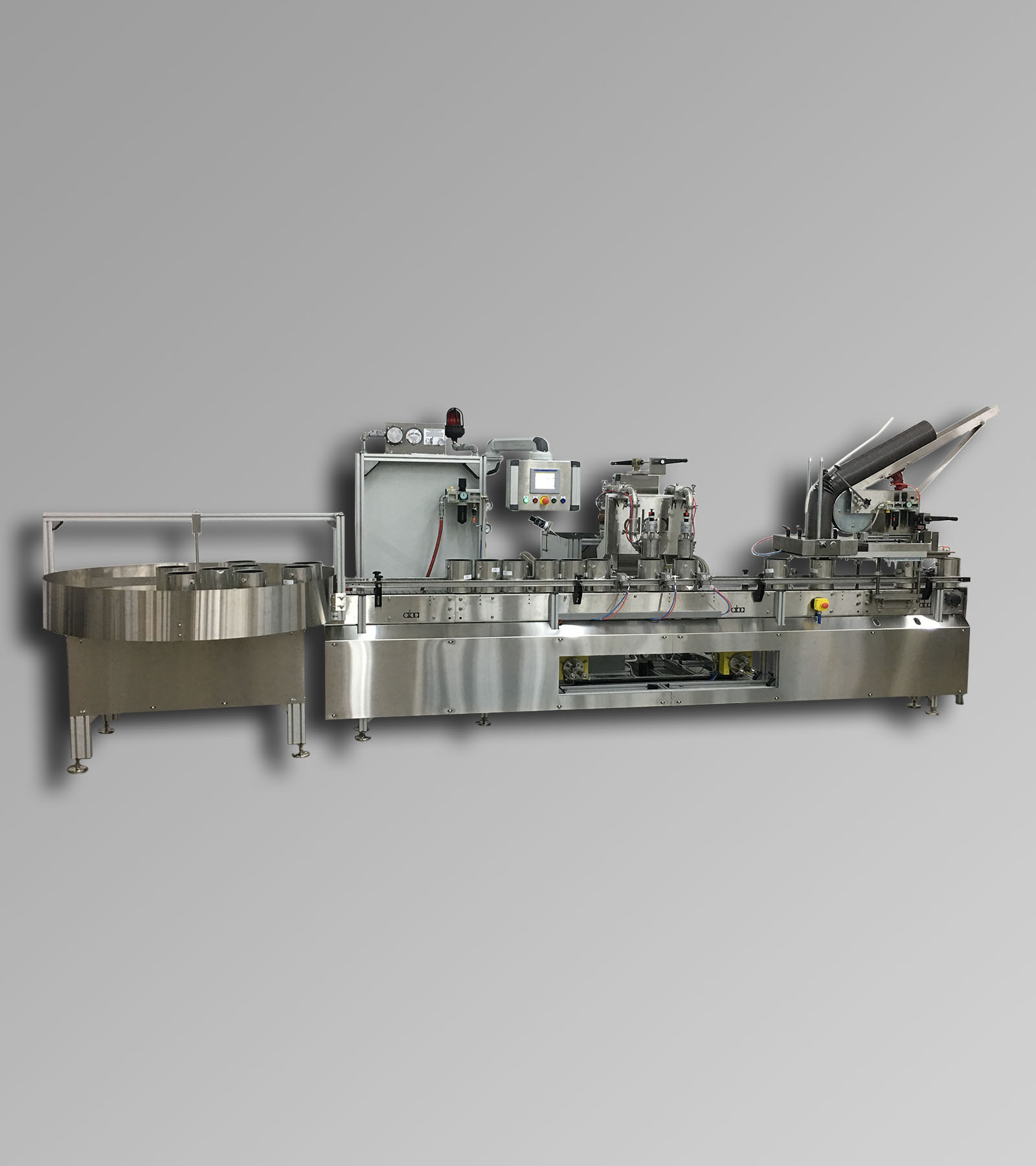

ABA-M426 is a 2 head top fill, volumetric filling machine designed for a C1D2 area. This machine has a number of additions which help to make it a quick, efficient, and valuable piece of equipment including swing frame fill heads on movable modules, a rotary infeed table, a lid dropper, and a roller lid press.

ABA is proud to offer an extensive selection of machines designed for hazardous environments to meet both C1D1 and C1D2 standards. For a closer look at what we offer or for more information, please visit the intrinsically safe machines on our website: http://www.abaltd.com/products/filling-machines/intrinsically-safe-explosion-proof.html

A popular design for 2 head machines is our Swing frame. This setup allows the operator to quickly move the heads so that they face the rear of the machine and can be positioned over a tank. Then, a simple flush feature on the screens lets the operator continuously run water, a cleaner, or product through the pumps and fill heads in order to clean or prime the machine. This eliminates additional equipment or undue messes and helps to keep the machine running more smoothly and accurately.

This machine features ABA's 1 gallon double acting volumetric piston pumps with gravity check valves, the ABA-80-GCV's. This one gallon pump is designed to fill from half pint to 5 quarts in a single cycle but can be set to fill larger container sizes as well with multiple cycles. All of the pumps we manufacture are constructed from stainless steel and Teflon wetted parts as well as cast end caps, tees, and elbows. These high quality parts make our pumps long lasting, efficient, and easy to maintain. In the vein of easy maintenance, all pumps are assembled using quick release clamps which makes it faster and easier than ever to keep them clean or to replace any parts necessary. The double acting design that we use for all of the pumps we manufacture is by far the more efficient and faster design and it also contributes to the extended lifespan of the pump and all wear parts. Simply stated, double acting refers to the presence of liquid on both sides of the piston cup.

This filling machine also features two individual fill modules which can be moved in and out according to what is being filled or if either of them requires cleaning. The fill modules are both outfitted with two volumetric pumps and two fill heads and also both feature a stainless steel product tank. The modules are easy to hook up to and remove from the main machine and then simply need to be rolled away.

The rotary infeed table supplied with this machine is just another factor in increasing the overall speed, efficiency, and performance of the line. Our rotary tables are 60" in diameter and feature stinaless steel sheet metal guards and a plated circular feed table. All container contact points are equipped with Teflon runners to prevent marking or damaging of containers or equipment. The ability to preload a large quantity of containers keeps the machine running continuously and alleviates the pressure on operators to be constantly feeding empty containers onto the infeed end of the machine, thus freeing them up to perform other tasks along the line.

This machine also features a top off system positioned after filling and prior to the containers getting lidded. The mounted top off nozzles deliver a burst of anti-skimming agent to the surface of the filled containers as they pass beneath.

ABA-M426 is also outfitted with a lid dropper with downstacker for additional lid capacity. Our ABA-LDHS lid dropper is a high speed unit designed to drop metal and plastic lids from 1/2 pint through 1 gallon sizes. This unit is not standalone and must be mounted to one of our ABA lid press units. The standard vertical hopper has a 24" lid capacity, but with the addition of the downstacker chute, that increases to 72" of extra capacity. All lid droppers use ratchet handles for simple size changeovers and are height adjustable via the crank handle located on the lid press. They also come with interchangeable star wheels for correct lid alignment and reach speeds of 60+ lids per minute.

Our 1 gallon roller lid press, ABA-PRESS-1NAR, is the unit onto which the aforementioned ABA-LDHS is mounted. This non-powered roller lid press is designed to press lids on half pint through 1 gallon containers and is height adjustable with the easy to use crank handle on the corner of the press. Stainless steel sheet metal guards the chains and sprockets associated with height adjustment, and the rollers are steel with stainless steel shafts.