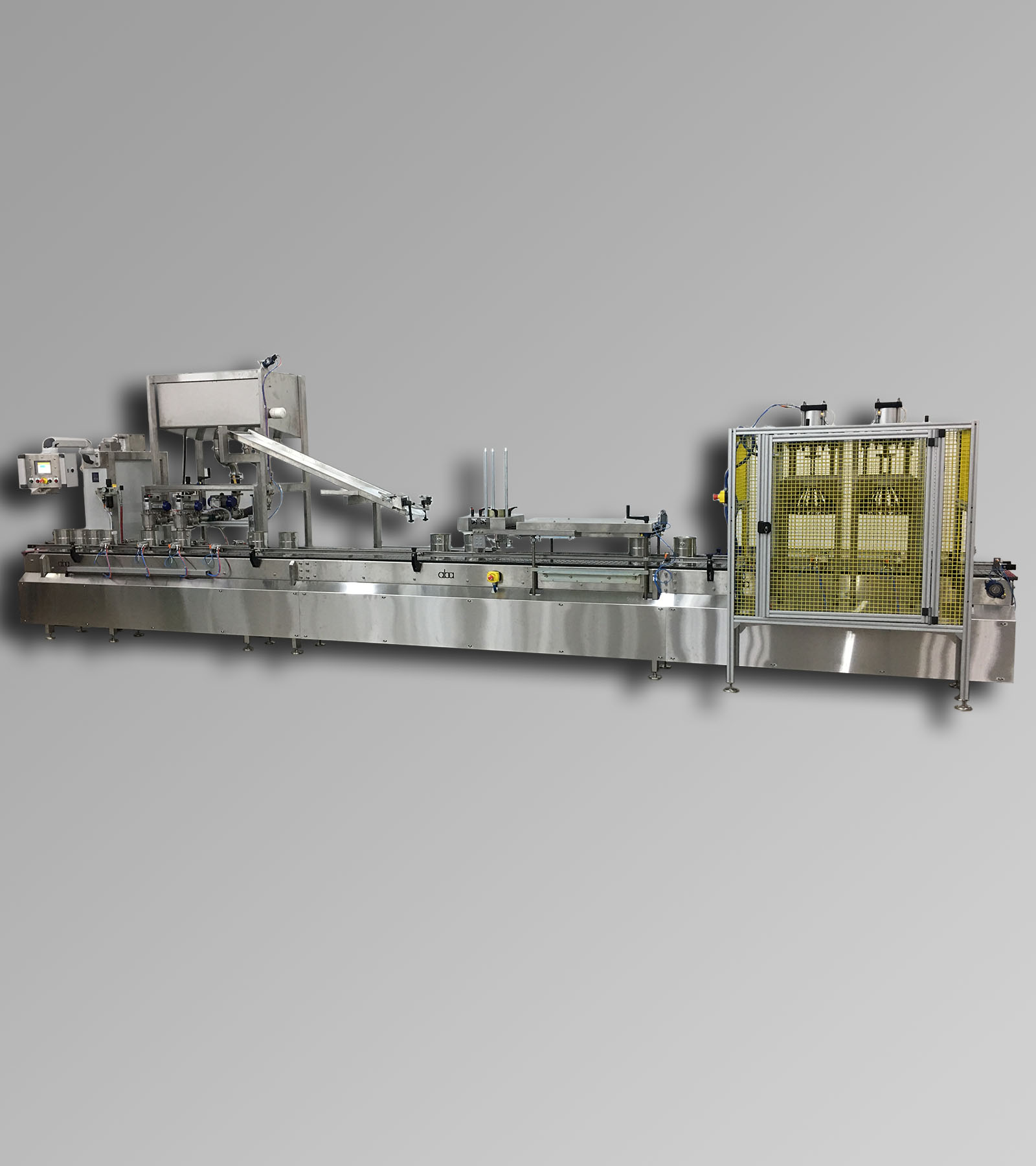

ABA's latest fully automatic net weight filling machine is a 2 head (with provisions for a later addition of a 3rd head) machine designed for a Class 1 Division 1 (C1D1) explosion proof area.

We believe our customers shouldn't have to compromise on the caliber of machinery they receive or their ability to customize it to fit their needs simply because they need a machine to fit into the specific criteria of being explosion proof. It is for that reason that we have worked hard to expand upon and improve our C1D1 and C1D2 designs to offer companies the best options for an intrinsically safe filling machine. For instance, this machine features a wildly successful component - the intrinsically safe mouse. This mouse is mounted onto the pendant arm and is used to control the HMI. This is a time and cost saving feature which increases the efficiency of the operator so he or she is free to focus on other components of the fill cycle.

ABA-M395 is not simply an explosion proof machine. This filler also boasts a number of features designed to improve throughput and efficiency and to maximize ROI and minimize waste and mess. Some of these include:

- A stainless steel semi-automatic lid chute which allows the operator to pre-load a number of lids at a time negating the need for manual lid placement. This lid chute is the perfect middle ground between manual placement of each individual lid and a fully automatic lid placing machine. For the budget conscious plant who still wants to negate the need for an operator to constantly be manning a lid placing section, this is a wonderful and flexible solution. The operator simply needs to load lids onto the stainless steel chute, and the motive force of the containers on the conveyor below will pull a lid off as it passes beneath.

- A high speed lid dropper unit for dropping smaller sized lids (1/2 pint - 1 gallon) drops lids onto the containers as they pass beneath it. This unit is mounted to our roller lid presses and is optionally available with a downstacker for additional lid capacity. Our lid droppers are also supplied with starwheels to ensure that only centered lids pass beneath the roller lid press.

- A 5 gallon roller lid press which uses 32 gradually declining steel rollers to firmly press on lids from pint-6 gallon pails is fully height adjustable using a simple crank handle on one corner of the unit. This press is designed to press the lids onto plastic containers and smaller metal containers alike. A stainless steel cover shields the operators from the chains and bearings utilized in the height adjustment.

- Dual crimp stations at the end of the line round out the great features on this machine. These two crimpers are designed to crimp the lids onto 5 gallon metal pails. The crimp tools are customized to the exact containers used by our customers and the safety guard protects operators and workers.

When the time come to look into new machinery for your fill line or to upgrade existing equipment, consider the high quality machines at ABA. For more information on this or any of the other filling machines we offer, please call (803) 396-0621, email: sales@abaltd.com, or send us a RFQ on our website and we would be happy to help you design your best machine.