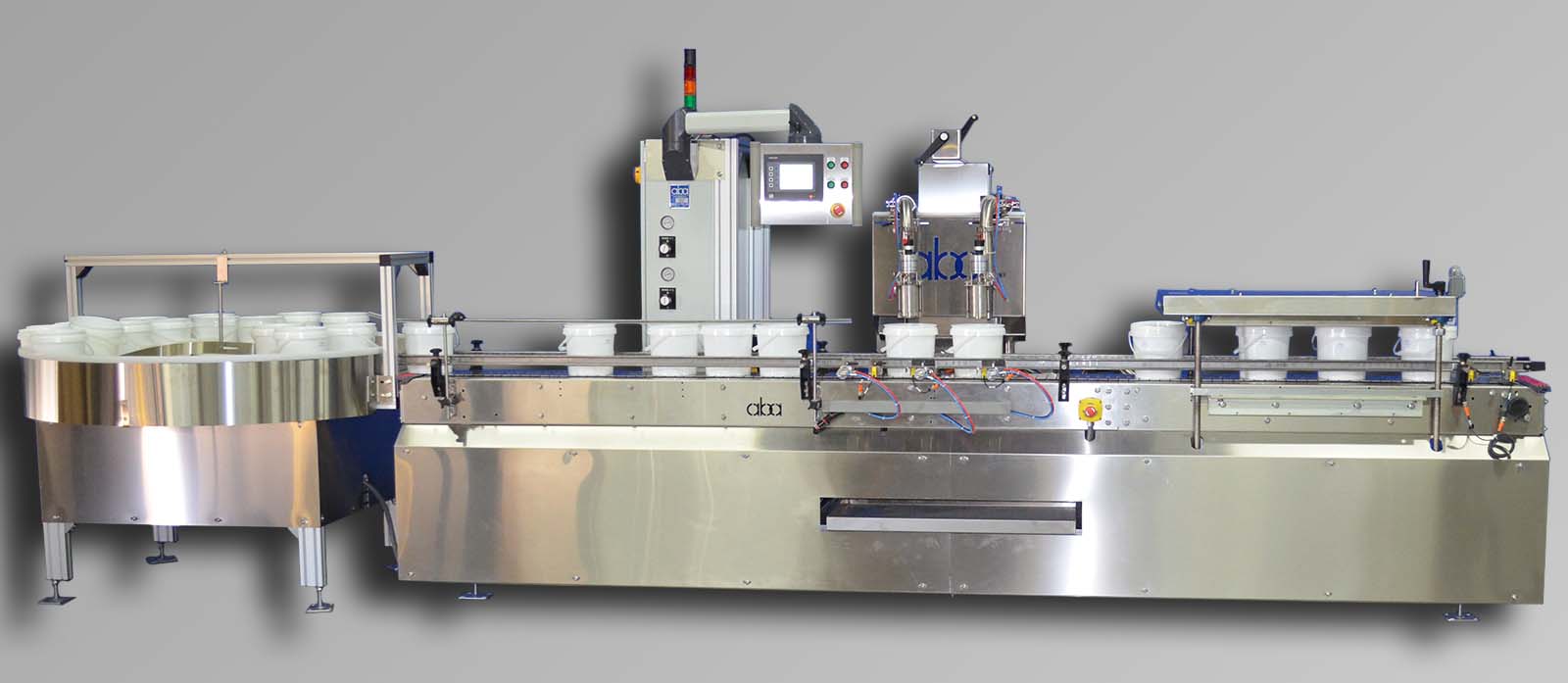

ABA-M327-2 is a two head volumetric filling machine with a swing frame, rotary infeed table, and roller lid press. Our popular swing frame design on two head units allows for quick and clean flushing, priming, and cleaning of the fill line. The operator just needs to push the fill heads around on their swivel joints until they are at the back of the machine, ideally over a tank. Then, select the flush option on the HMI and the system will cycle product, water, cleaning solution, etc. through until the operator stops the flush cycle.

This machine features our 1 gallon positive displacement double acting piston pumps, ABA-80. All of our pumps are made with high quality stainless steel, Teflon, and cast parts and are designed to be easy to clean and maintain with quick release clamps. We only offer double acting piston pumps, because they are the most efficient and longest lasting. With product on both sides of the piston, unnecessary wear on the parts is avoided and the longevity of the pump is extended.

Also featured on this machine is our 60" diameter rotary infeed table. This table is made with an aluminum frame and a plated circular top, but can be optionally supplied with stainless steel frame and top. Rotary tables are a huge advantage to operators when increasing speed and efficiency of a fill line by allowing them to pre-load a large number of containers and then move on to manage or work with other aspects of the fill line.

Our 5 gallon roller lid press, ABA-PRESS-5NAR, is constructed using 32 x 1" declining rollers which firmly press lids onto containers. There is a height adjustment handle on one corner of the unit and the chain and sprockets are covered for operator safety with a stainless steel sheet metal cover. Also featured on this press is our no lid detector unit which, as the name suggests, detects when a container passes beneath it with no lid. If a lidless container is detected, the conveyor stops and the fill cycle continues until the containers are filled and then stops as well until the error is rectified. This prevents large scale spills or congestion on the line.

Please visit our website or our youtube page for more information, to see more products and machines, and to view our equipment in action. If you have any questions or would like to work with our sales and engineering teams to design a fill line for your plant, please contact us today via phone: (803) 396-0621, email: sales@abaltd.com, or via our website: request a quote. We look forward to hearing from you and to helping you solve your filling problems.